by

Linda Kleineberg

| May 31, 2013

Concrete must be consolidated properly to achieve a high-quality end product - strength, durability, uniformity, and beauty are all affected by the consolidation process. Vibration is the most common method used to consolidate concrete. (Guide for Consolidation of Concrete, ACI-309R-96, Section 3.2)

Vibration consists of subjecting freshly placed concrete to rapid vibratory impulses which liquefy the mortar and drastically reduce the internal friction between aggregate particles. While in this condition, concrete settles under the action of gravity (sometimes aided by other forces). When vibration is discontinued, friction is reestablished. (ACI-309-R-96, Section 4)

Concrete workers - Contractors, Precasters, Concrete Countertop Artisans, Ornamental Concrete Artisans, etc. - call VIBCO for assistance with the selection and placement/lay-out of their external concrete vibrators. During VIBCO's 50 years in business, we've had the opportunity to see thousands of concrete projects. See VIBCO Concrete Vibrator Application Stories Now

5 Things to Know About External Concrete Vibrators

1. The position and layout of external concrete vibrators is critical. External concrete vibrators have radii of influence that is a hemisphere extending out from the vibrator location. You should plan your vibrator placement accordingly and consult with a VIBCO Vibrators concrete expert.

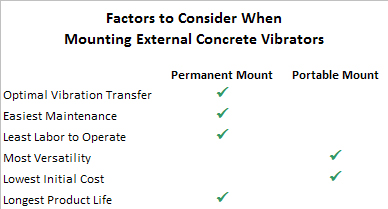

2. Deciding how you will mount your vibrators is an important first step in creating your vibration plan. There are several important factors to consider when choosing whether to use portable mounts or permanently mount your external concrete vibrators including vibration transfer, maintenance, labor, versatility, cost, and product life. Read VIBCO's Concrete Vibrators Handbook and Catalog for more detailed information.

3. Proper vibration of fresh concrete is the best way to prevent cold joints, bugholes, and honeycombing. Proper external vibration of concrete helps to mitigate these common defects. When using external concrete vibrators, it is important to rest the concrete forms on wood beams or rubber mats to prevent the form from vibrating against the floor and surrounding forms. It is equally important to "stiffen up" or reinforce forms in order to provide uniform vibration transfer and prevent leaks.

4. External concrete vibrators can enhance predictability and repeatability in your quality. There are many variables that contribute to concrete quality. One key variable can be the skill and craftsmanship of an internal vibrator operator(s). Many European countries require a vibrator operator to complete a 10-year apprenticeship and be licensed, whereas in the United States, no license or formal training is required. ("Internal or External Vibration", Concrete Construction) The variability in technique, equipment, skill, and attention of an internal vibrator operator can have a dramatic impact on finish quality. Using external vibrators provides a known variable that can be fine-tuned and adjusted in predictable, repeatable ways.

5. Best practice is to plan ahead for your external vibration needs and to have spares on hand. Good planning will make your entire concrete operation run more smoothly - this includes the use of external concrete vibrators. Pre-installing brackets, having a clear pattern for placement and movement of portable vibrators, ensuring adequate air supply for pneumatic vibrators, tightening/reinforcing formwork if necessary, and having an organized, ready work-site will help to ensure a great finished product. Repairing or redoing concrete because of defects and poor quality is a time-consuming and expensive process. Planning ahead and having a solid understanding of vibration technique can help to eliminate the costs associated with defects.

Contact VIBCO today for assistance with external concrete vibrators.