by

Linda Kleineberg

| Apr 23, 2013

An Electric vibrator is an engineered solution. It must be installed and operated according to the manufacturer's instructions to get maximum benefits and longest product life.

Improve Your Electric Vibrator Performance Today!

If you have problems with the performance and operation of your electric vibrators, it's usually due to an easily fixable problem with the mount or installation. Please refer to our online manuals for complete instructions and best practices for VIBCO electric vibrators.

We can help you fix any of these electric vibrator issues...

- Vibrator draws high amps and "kicks" the breaker

- Vibrator "burns out" after a short time in operation

- Performance or useful life of a replacement vibrator is significantly lower than previously installed equipment

- Vibrator makes a humming noise, but does not run properly

Installation Error is the Most Common Root Cause

Answer the following questions to get to the root cause of your electric vibrator performance problem. Still stumped? Use our Virtual Van Visit program to diagnose and solve your vibrator problems.

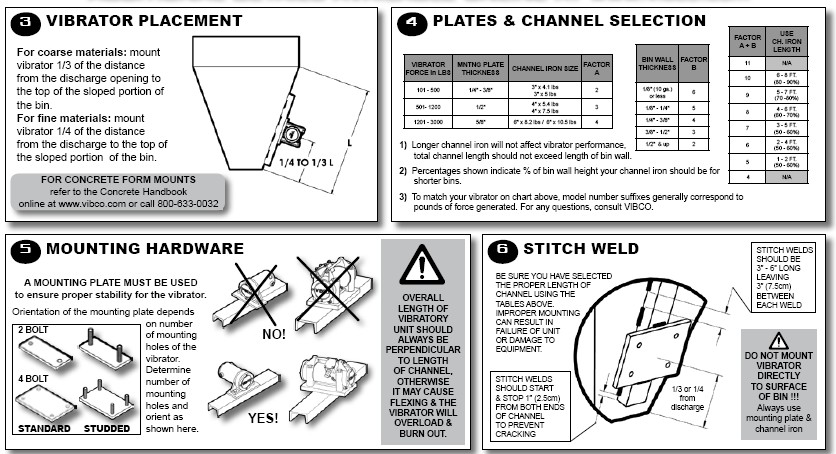

Is your electric vibrator mounted directly to the bin or hopper rather than to a mounting plate and channel iron?

Mounting directly to the bin or hopper can cause the bin or hopper to crack, can cause damage to your vibrators, and can cause a high amperage draw. It is critical for electric vibrators to be mounted to a plate and channel iron combination.

Is your electric vibrator mounted to just a plate or just a channel iron?

It is extremely important to mount electric vibrators in the manner recommended by the manufacturer. Vibration, while an effective material flow aid, can be a destructive force if it is not applied correctly. Using a mounting plate or channel iron alone may not be sufficient to secure and isolate the vibratory force. For best results, use a channel iron and mounting plate together.

Is your electric vibrator mounted in the wrong position or orientation?

Electric units should be mounted perpendicular to the channel iron. The mounting plate should be checked for warping and, if necessary, shimmed to achieve a tight seal. Any looseness or "give" will prevent the vibratory force from being properly isolated and transferred. A sufficient length of channel iron should be used to distribute the force along the bin or hopper walls. Refer to our service manuals to determine the correct length of channel iron.

Is your electric vibrator mount correctly welded, shimmed and/or bolted?

Mounting channel should be stitch-welded to the hopper or bin, with no welds on the corners of the channel. Welding on the corners of the channel can lead to bin damage and unit failure. All bolts should be tightened down securely to prevent slippage and all shims should be positioned to keep the mounting plate flat.

Remember - your electric vibrator mount is critical to maximizing the benefits of your equipment. Our technical support staff is happy to assist you to ensure that you get the most out of your VIBCO electric vibrators. Contact us 24 hours per day, 7 days per week at 800-633-0032 for assistance.

| 1. | Your electric vibrator is drawing high amps and kicking the breaker. |

| 2. | Your electric vibrator is burning out after just a short time in operation. |

| 3. | Performance or useful life of your new electric vibrator is significantly lower than a previous electric vibrator. |

| 4. | Your electric vibrator fails shortly after being repaired. |

| 5. | Your electric vibrator makes a humming noise, but does not run properly. |