Quick Links

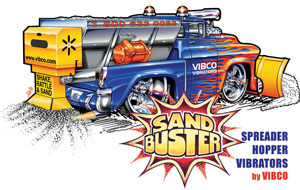

Featured Product: Sell VIBCO SandBuster™ Vibrators This Month

Industry Focus: Candy and Chewing Gum Manufacturers

Industry Focus: Clay Refractories

"Talk the Talk" Lean Word: Hoshin Kanri

See how VIBCO SandBuster Spreader Hopper Vibrators help keep Ice Control Operators safe and productive.

"Talk the Talk" Lean Manufacturing Word of the Week: Hoshin Kanri

Learn more about Hoshin Kanri at http://en.wikipedia.org/wiki/Hoshin_Kanri Also called policy deployment, hoshin planning, or simply hoshin (as in "FY12 Hoshin"), it is a strategic planning/strategic management methodology based on a concept popularized in Japan in the late 1950s by Professor Kaoru Ishikawa: "Each person is the expert in his or her own job, and Japanese TQC [Total Quality Control] is designed to use the collective thinking power of all employees to make their organization the best in its field." This is the fundamental principle of hoshin kanri. In Professor Ishikawa's words in his book What Is Total Quality Control?: "Top managers and middle managers must be bold enough to delegate as much authority as possible. That is the way to establish respect for humanity as your management philosophy. It is a management system in which all employees participate, from the top down and from the bottom up, and humanity is fully respected." Adaptations of the concept have since been developed by many others, among them Dr. Yoji Akao, that use a Deming cycle (Plan-Do-Check-Act) to create goals, choose control points (measurable milestones), and link daily control activities to company strategy.[2]

The discipline of hoshin kanri is intended to help an organization:

- Focus on a shared goal.

- Communicate that goal to all leaders.

- Involve all leaders in planning to achieve the goal.

- Hold participants accountable for achieving their part of the plan.

It assumes daily controls and performance measures are in place: "With hoshin kanri... the daily crush of events and quarterly bottom-line pressures do not take precedence over strategic plans; rather, these short-term activities are determined and managed by the plans themselves."[3]

In Japanese, hoshin means "compass needle" or "direction". Kanri means "management" or "control".[4] The name suggests how hoshin planning aligns an organization toward accomplishing a single goal.

Learn more about VIBCO's Lean Manufacturing Program and Leadership